By Paul Temple

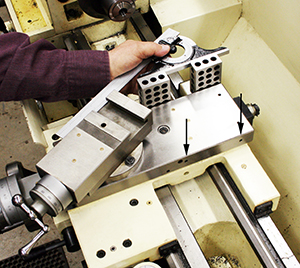

Setting the compound rest angle on a lathe can be frustrating since the engraved protractor scale is frequently hidden from view by the compound rest. Most modern lathes have cross slides and compound rests with outer surfaces accurately squared and aligned with their bed ways. This rectangular shape can be taken advantage of for setting the compound rest angle, but only if a cross slide edge can be moved up to the same plane as the compound rest. The photo shows how I do this translation.

Four 1/4-20 holes were blind tapped into the two vertical edges of the cross slide, 1” and 5” from the far end. In the photo, two of the holes are identified with arrows and the other two, on the opposite side of the cross slide, are being used to hold 123 blocks, using washers and 1-1/2” long cap screws. On my 13” JET lathe these blocks are tall enough to allow me to set the compound rest angle. By having four block locations, I have always been able to find configurations that can be used regardless of the desired compound rest angle.

In the photo a combination protractor is being used to set a 29-1/2° threading angle. I also enjoy using a 19th century Brown and Sharpe draftsman’s protractor that reads to 5 minutes of arc for setting more precise angles. When still more precision is needed, the angle can be established with a sine bar set up on a surface plate and then a protractor can be used to transfer the established angle to the compound rest.

As a final touch, when not in use I put 1/4-20 setscrews into all the tapped holes to keep them clean and looking “finished.” And best of all, I can now do without the awkward protractor scale that is engraved into the top of the cross slide!

Thanks, Paul, your subscription has been extended by an issue!