By Robert Beason

DeWalt makes a small sander that is very widely used by woodworkers. Many people I know own more than one of them. The platen on the sander is made of hard plastic on top with a spongy bottom surface that has a hook and loop surface for attaching common sanding disks. The problem with this design is that the platen wears out quickly and the paper quits holding; plus, the surface becomes uneven and it is hard to sand a flat surface and keep it flat with a worn platen.

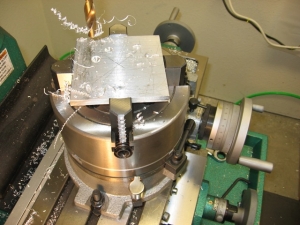

I wanted a hard, flat surface for the sanding pad, and wanted one that adhered firmly to the hook and loop material and lasted a long time. My solution was a simple milling machine project, using a small piece of aluminum.

Taking dimensions from the old platen, I drilled the holes using the rotary table. Next, I trimmed the OD of the platen to size.

Lee Valley sells a heavy duty hook and loop material with an adhesive backing that sticks well to these flat aluminum platens. This design has proven to be a very satisfactory solution to the problem and is certainly a lower cost alternative than the $27 replacement platens!

Thanks, Robert, your subscription has been extended by an issue!